Manufacture Oversized Hoodies

The demand for oversized hoodies has surged in recent years, driven by trends in streetwear, athleisure, and comfort-focused fashion. Whether you’re a startup designer, a fashion brand, or an entrepreneur looking to enter the apparel market, understanding the manufacturing process of oversized hoodies is crucial. This guide delves into the essential steps, cost considerations, and best practices to help you navigate the complexities of hoodie production.

1. Design Development and Technical Specifications

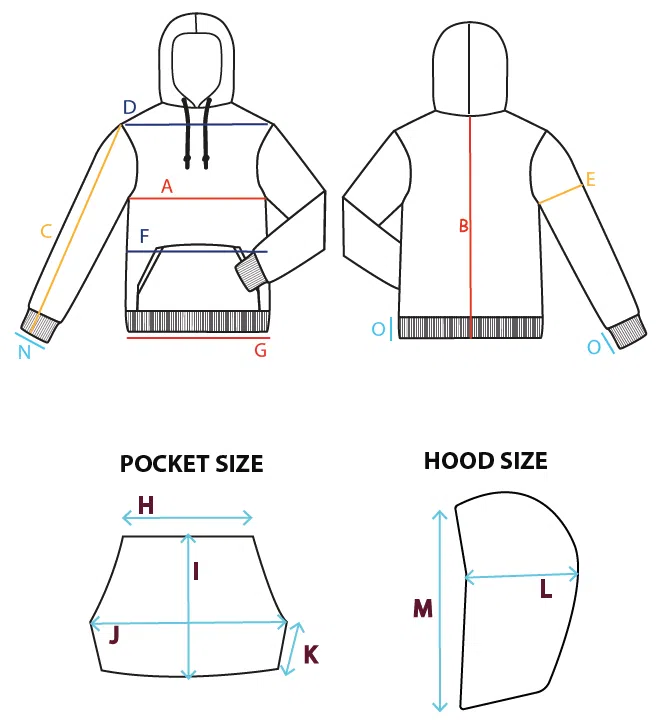

The journey begins with conceptualizing your oversized hoodie design. This phase involves creating detailed technical specifications, including:

-

Technical Pack (Tech Pack): A comprehensive document outlining design sketches, fabric specifications, colorways, stitching details, and measurements.

-

Pattern Making: Developing patterns that reflect the oversized fit, ensuring comfort and style.

-

Prototyping: Creating initial samples to evaluate design elements and fit.

At PRP Apparel, we provide full support in custom hoodie design and pattern making. You can learn more about our design process here.

2. Material Selection for Hoodies

Choosing the right fabric is pivotal for the quality and comfort of your oversized hoodie. Common fabric options include:

-

Cotton: Soft, breathable, and comfortable, ideal for casual wear.

-

Polyester Blends: Durable and moisture-wicking, suitable for activewear.

-

Organic Materials: Eco-friendly options like organic cotton or recycled polyester appeal to sustainability-conscious consumers.

The choice of fabric influences the hoodie’s feel, durability, and production cost. At PRP Apparel, we offer a variety of sustainable fabrics for custom clothing options. Check out our sustainable fabric options.

3. Sourcing Manufacturers

Identifying a reliable manufacturer is crucial for quality control and timely delivery. Consider the following when selecting a manufacturer:

-

Experience with Oversized Garments: Ensure the manufacturer has expertise in producing oversized apparel.

-

Production Capacity: Assess their ability to handle your order volume.

-

Quality Control Measures: Inquire about their quality assurance processes.

-

Location: Decide between domestic or overseas production based on cost, lead time, and communication preferences.

At PRP Apparel, we offer both domestic and international production options. Explore more about our manufacturing services.

4. Sampling and Fit Testing

Before proceeding with bulk production, it’s essential to create samples and conduct fit testing:

-

Sample Production: Manufacture a small batch to evaluate design and construction.

-

Fit Testing: Assess the oversized fit on different body types to ensure comfort and style.

-

Feedback Collection: Gather input from potential customers or focus groups to refine the design.

We assist our clients in creating high-quality hoodie samples for market testing. Learn more about our custom hoodie samples.

5. Bulk Production and Final Steps

Once the samples are approved, proceed with bulk production:

-

Production Scheduling: Coordinate timelines to align with market launch dates.

-

Quality Assurance: Implement checks at various stages to maintain consistency.

-

Logistics Planning: Organize packaging, labeling, and shipping to distribution centers or retailers.

At PRP Apparel, we ensure that your oversized hoodie production runs smoothly from start to finish. Discover more about our bulk production services.

6. Pricing Models and Cost Considerations

The cost of manufacturing oversized hoodies varies based on several factors:

| Factor | Impact on Pricing |

|---|---|

| Material Costs | Premium fabrics like organic cotton or specialty blends will increase costs. |

| Customization | Embroidery, screen printing, or patchwork adds to the price per unit. |

| Labor | Domestic production may have higher labor costs compared to overseas manufacturing. |

| Order Volume | Larger orders often result in lower per-unit costs. |

It’s essential to balance quality and cost to ensure profitability while meeting consumer expectations. Learn more about cost-effective manufacturing and MOQ options on our Pricing Page.

7. Best Practices for Successful Hoodie Manufacturing

-

Maintain Design Consistency: Ensure all design elements align with your brand identity.

-

Prioritize Quality Control: Regular inspections during production can prevent defects.

-

Communicate Clearly with Manufacturers: Establishing a strong relationship fosters collaboration and problem-solving.

-

Stay Informed on Trends: Keeping up with fashion trends ensures your designs remain relevant.

By adhering to these best practices, you can produce high-quality oversized hoodies that resonate with your target market.

8. Case Study: American Giant’s Hoodie Manufacturing Success

American Giant, a U.S.-based apparel company, gained recognition for its high-quality hoodies made in the U.S., leading to a surge in demand. The company emphasizes meticulous design and domestic manufacturing to ensure product quality. Their approach highlights the importance of quality control and brand consistency in the competitive apparel market.

Read more about American Giant’s story here.

Conclusion

Manufacturing oversized hoodies involves a multifaceted process that requires careful planning and execution. From design development to bulk production, each step plays a crucial role in delivering a product that meets consumer expectations. By understanding the intricacies of hoodie manufacturing and implementing best practices, you can successfully navigate the complexities of the apparel industry.

At PRP Apparel, we specialize in providing custom hoodie manufacturing services, ensuring your designs are brought to life with the highest standards. Explore our Contact Page to get started with your hoodie project.

Join our Facebook community and be the first to know